Wastewater solutions for chemical, electronic, textile, mining, and food industries

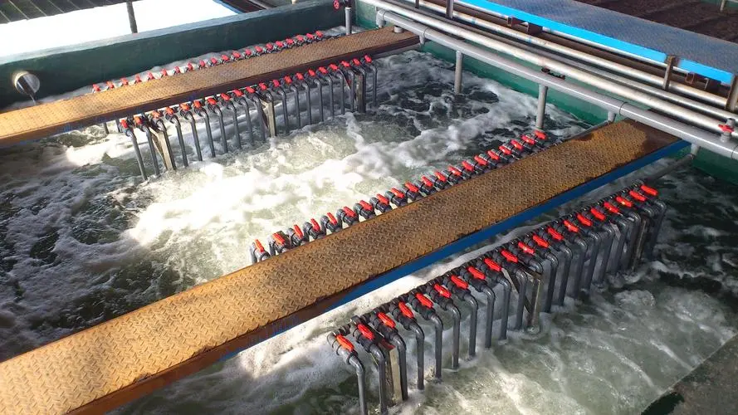

Membrane bioreactor (MBR) is a new water treatment technology that combines membrane separation units with biological treatment units. High treatment efficiency and good effluent quality; Compact equipment and small footprint; Easy to achieve automatic control and simple operation management. Since the 1980s, this technology has been increasingly valued and has become one of the research hotspots. Membrane bioreactors have been applied in more than ten countries, including the United States, Germany, France, and Egypt, with scales ranging from 6m3/d to 13000m3/d.

Advantages and disadvantages of MBR

Membrane Bioreactor (MBR) is a new and efficient sewage treatment technology that combines membrane separation and biological treatment. Membrane separation technology was first applied in the microbial fermentation industry. With the development of membrane materials and membrane manufacturing technology, its application fields continue to expand, involving multiple fields such as chemical industry, electronics, light industry, textile, metallurgy, food, petrochemical industry, and sewage treatment.

It has great flexibility and practicality. The MBR process has a short process and a small footprint. Flexible water treatment (increase or decrease membrane components).

Solved the problem of difficult disposal of excess sludge. The production of excess sludge is very small, and it is generally discharged once a month.

Relevant news