Waste Oil Distillation Plant

Product Details

- About Waste oil distillation plant

Raw material: waste motor oil/tyre pyrolysis oil/plastic pyrolysis oil

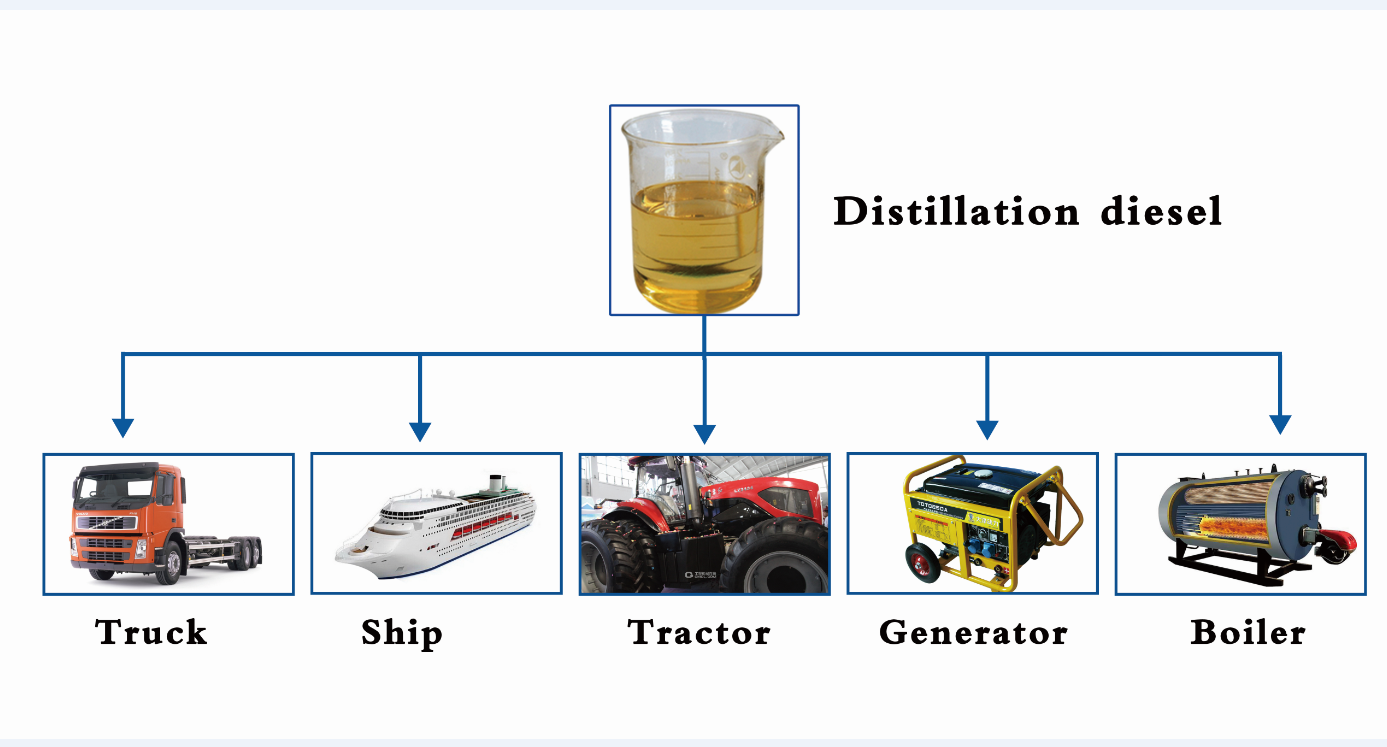

Waste oil distillation plant can treat a variety of waste engine oil, waste tyre pyrolysis oil and waste plastic pyrolysis oil and get high quality diesel oil . The diesel oil got is in high quality and can be used for tractors, trucks, generators, boilers, etc. Waste oil distillation machine is the most advanced technology in the waste oil recycling industry and suitable for large-scale industrial production.

MAIN ADVANTAGES

Vertical design:

Our distillation reactor adopts vertical design which can achieve the automatic slagging. Thus to save time and energy in the slagging process. Also can prevent the workers hurting from the hot asphalt discharge.

Double heating methods:

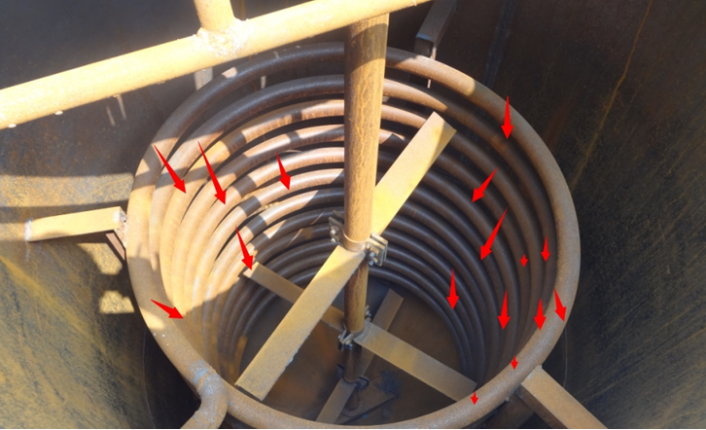

Fuel heating & Coil heater heating

Except the fuel heating directly from the bottom of the distillation reactor, the inner coil heater can make the heating evenly and fast, it can keep processing 3 batches oil in 2 days without stop. And conduction oil is for recycle use, which can save a lot of fuel.

Inner structure of the distillation reactor

Clean technology:

This distillation process adopts catalysis & fractionation technology. Compared to the chemical processing, this technology does not generate secondary waste, and makes the whole operation process much safer.

SAFETY CONTROL

1) Reactor design:

The distillation reactor is made by high quality boiler plate, which has high temperature resistance.

And the reactor is made strictly according to pressure vessel standard which adopts the round-shape

reactor head, which could make sure the strong connection to the reactor body, with good pressure

buffer performance.

2) Slagging design:

In order to make the slagging process safe, the distillation reactor was designed into vertical

structure, which could make automatic slagging without hurting the workers.

3) Water seal:

Water seal is a kind of anti-fire device, which could slow down speed of the waste gas and prevent

the waste gas flowing back to the system and cause high pressure and fire.

- Final products

- Distillation diesel 85%-90%

- Asphalt 5-10%

- 3D image of 5 TPD waste oil distillation plant

Process drawing of 5 TPD waste oil distillation plant

- Equipment list

General equipment list of DOING 5 TPD waste oil distillation plant

|

No. |

Description |

Photo for reference |

Specification |

Quantity |

Remarks |

|

1 |

Distillation reactor (蒸馏釜) |

|

Q245R Φ1700mm*H3050mm*14mm

|

1set |

Outside insulation with 304 SS |

|

2 |

Furnace base (炉膛底座) |

|

Φ1700mm*H1300mm |

1set |

|

|

3 |

Buffer chamber (缓冲罐) |

|

Q235 Φ600mm*H2000mm *5mm |

1set |

With fillers inside |

|

4 |

Horizontal shell-tube condenser (列管泠凝器)

|

|

Q235 Φ900mm×H3500mm *5mm |

2 sets |

Flange thickness20mm Shell-tube SS With DN150 gasket for inlet & outlet with foundation 进出口DN150配基座 |

|

5 |

Oil tank(油罐) |

|

Q235 Ф1500mm×δ5mm×L3000mm |

1set |

|

|

6 |

Water seal (水封) |

|

Q235 Φ600mm*H1000mm *5mm

|

1 set |

With DN100 gasket for inlet & outlet两个DN100进气口 |

|

7 |

Smoke scrubber (水沫除尘器)

|

|

Q235 Φ800mm*H2500mm×δ5mm |

1set |

|

|

8 |

De-waxing reactor(脱胶反应器)

|

|

Φ1300mm*L2500*6mm |

1set |

Stainless steel |

|

9 |

Odor removal (除味反应器)

|

|

Φ1300mm*L2500*6mm |

1set |

|

OPTIONAL SYSTEM

Oil purification system(De-coloring)(脱色过滤系统)

|

No. |

Description |

Photo for reference |

Specification |

Quantity |

Remarks |

|

1 |

White clay reactor (脱色锅) |

|

Q235 Φ1500×2250 Φ600×700 |

1pcs |

With installation material |

|

2 |

Leaf filter press (叶片过滤机) |

|

15㎡ |

1set |

|

|

3 |

Filtering pump(过滤泵) |

|

TSB50-32-160 |

1set |

|

|

4 |

Vacuum (负压) |

|

Q235 1000 mm×1200 mm×H950mm×δ4mm |

1set |

|

|

5 |

Bag filter (精密过滤机) |

|

0.5 m2 |

2 sets |

|

Fast heating system

|

No. |

Description |

Photo for reference |

Specification |

Quantity |

Remarks |

|

1 |

Heat transfer oil boiler |

|

YGL-240A |

1 set |

|

|

2 |

Heat transfer oil tank |

|

Φ900mm*L1500mm |

1set |

|

|

3 |

Heat transfer oil buffer tank |

|

Φ480mm*L600mm |

1 set |

|

If you are interested in our products, please contact us and JEPT will provide you with more high-quality products and services

Online Messages