Solution for using plastic waste to generate power

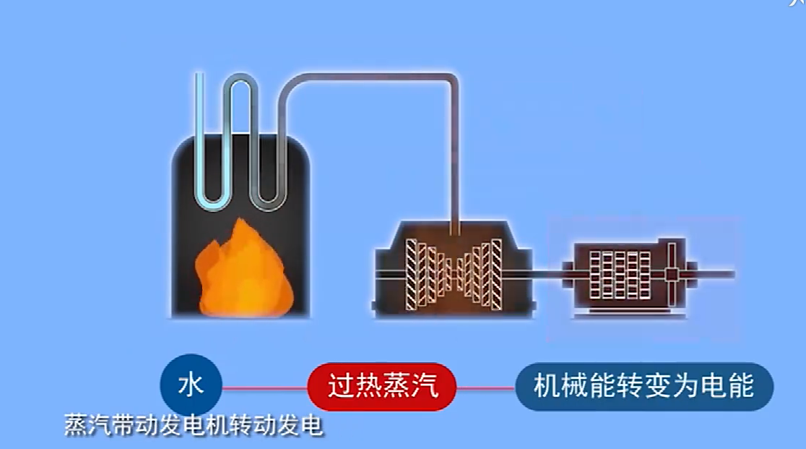

After collecting plastic waste, we add some auxiliary fuel to burn it, and then we use a series of equipment to convert heat energy into electricity. Waste plastic has the highest calorific value, with a calorific value of 32570KJ/Kg. Waste plastic only accounts for about 15% of the total garbage content, but its calorific value accounts for over 40% of the total garbage calorific value.

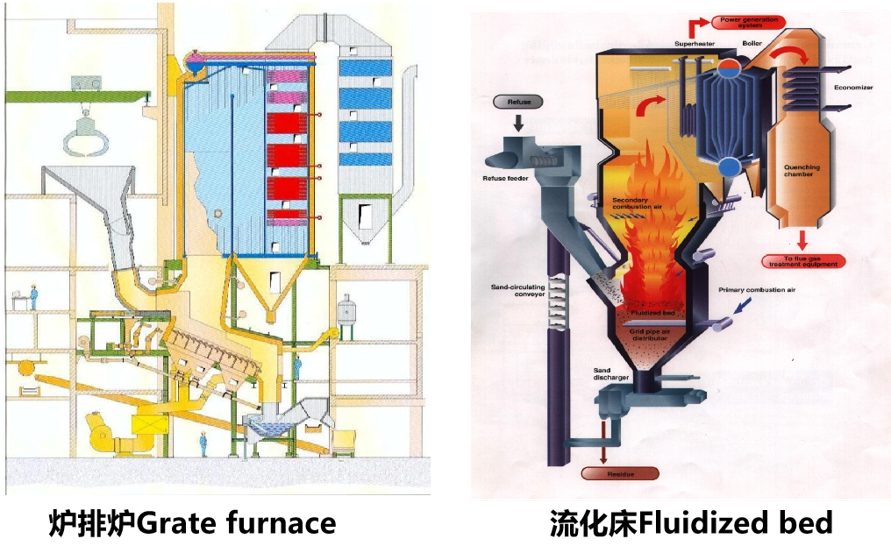

Grate furnace process and fluidized bed process

The grate furnace is plagued by dioxins, and the fluidized bed control system is relatively complex.

Which process is technically more suitable for urban waste treatment? In the market field, there is no clear winner between grate furnace and fluidized bed technology. If we can ensure that the moisture and ash content of plastic waste are controlled within the boiler design range, we suggest choosing the grate furnace process. If the composition of plastic waste is complex, it is difficult for us to ensure that the moisture and ash are controlled within the design range of the boiler. We suggest choosing a fluidized bed process.

Relevant news